FLYNYTT -01 – 2022

the world keeps talking about us

Marino Boric, Flying Legend for Flynytt,

Flying Legend

Become a Fighter pilot for more than a day

Rebirth of the legend for UL pilots and homebuilders

Today’s UL market offers almost everything for an UL pilot and an experiential aircraft builder – many offers are alike and way too many aircraft -specially the composite ones – are sometimes difficult to distinguish from each other. The company Flying Legend from Italy is different – way different – offering something different, not only in a look but even in an emotions. It offers a sensation almost all pilots dream of: to be a fighter pilot even for a single day. If you want you can be that even for the rest of your life, just buy or build your dream. OK, not to overwhelm your wallet, Flying Legend “shrink-ed” the original Tucano and offers the dream in a 1:70 scale.

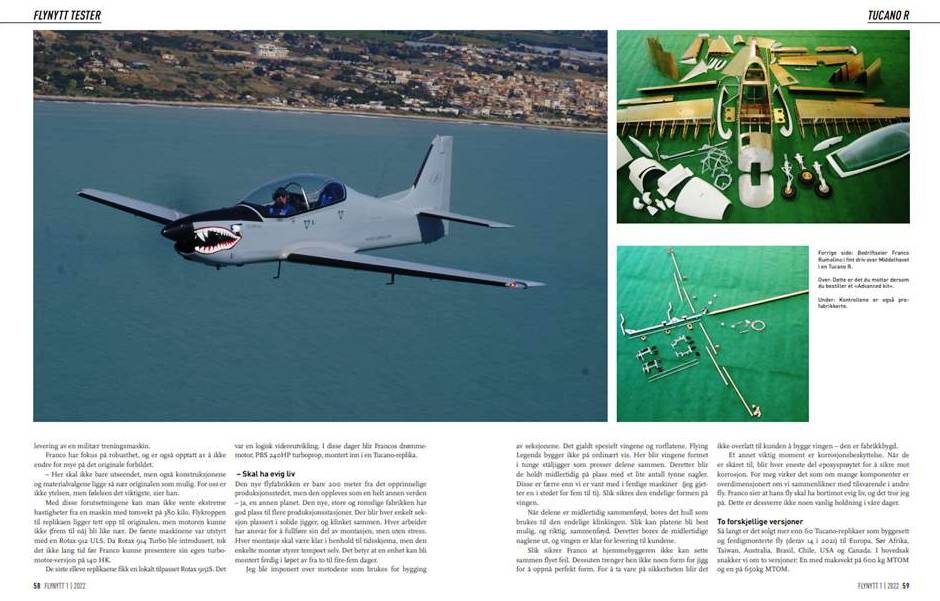

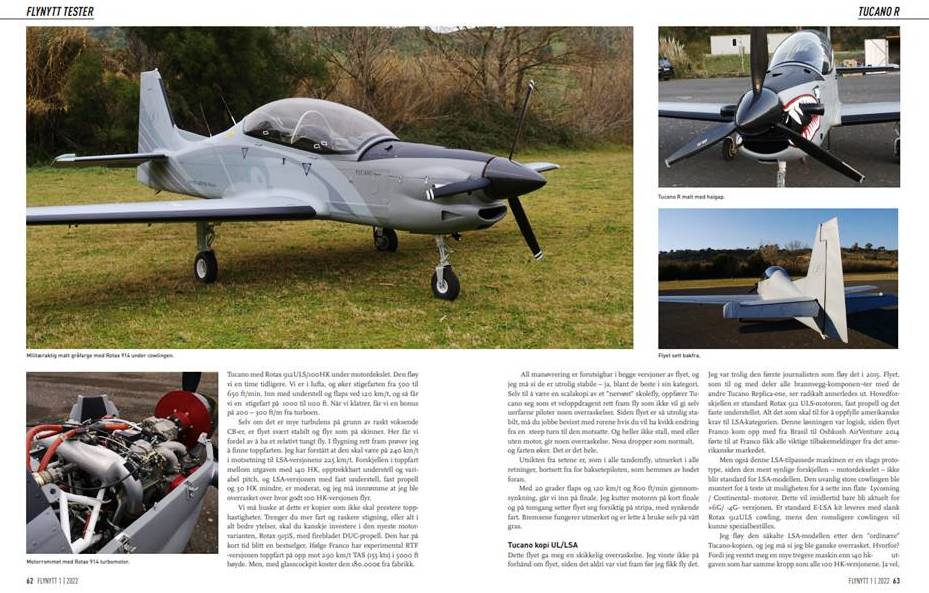

In the land of lemons, in the middle of Sicily, an avid skydiver, owner of a metal processing company, Franco Rummolino, decided some 14 years ago to build airplanes he was dreaming of. He has not decided to build just “any” aircraft, no, he decided to build a modern replica of his dreams: The Embraer EMB-312 Tucano. Flying Legend debuted the product in Europe at the AERO 2012, and in 2014 on the AirVenture in the US. The serial production started a decade ago and it was continuously refined till today; in 2022 we will whiteness the rebirth of the “real” Tucano replica powered by a turbine powerplant. I was the first journalists able to see & to fly the Tucano replica ten years ago – the prototype flown those days has been continuously improved, several versions were developed and after some 70 units sold, powered by a Rotax piston engines, the ultimate version powered by the 240HP Czech PBS turboprop will shortly take-off.

In a year 2014, after landing in Catania on Sicily’s, Franco brings me to the new Flying Legend factory. From the airport, we drive 70 km inland, heading west toward Caltagirone – world famous for its ceramic artistic tiles where Franco owns two companies: Barum and Flying Legend. Barum is an industrial metal processing plant while Flying Legend is manufacturing airplanes. The industrial area of Caltagirone shows up and we stop in front of the older Barum plant. Upon arrival I meet the company co-owner, Giacomo Bandiera, and we inspect the plant. It is early afternoon and in the metal processing plant some 30 employees are manufacturing components for the chemical, oil-processing and nautical industry. I see lot of industrial parts but not a single airplane – two years ago there was a small corner in the building in which aircraft parts and assembly jigs were visible. Giacomo and Franco re-located the airplane manufacturing 200 meters away in the same industrial park by the end of 2013. In the magnificent new building Flying Legend now has 400 square meters of offices and close to 1000 square meters of production area.

From a skydiver to airplane manufacturer

Franco was (and still is) a passionate skydiver. Somewhere in 2009, he decided to start the aircraft production of the Brazilian all-metal aircraft trainer Embraer EMB-312 Tucano in a scale 1:70 under the name Flying Legend. The Tucano Replica maiden flight was made in 2011. The initial idea was to sell the Tucano Replica only as a kit but early the RTF (Ready-to-Fly) production started. Initially the Tucano Replica belonged only to the experimental class of aircraft with a MTOM of 600 kg and was designed for the load factor of + 4.4 / -2.2g. This changed pretty soon because a newer version of Tucano replica with a higher load factor of +6, -3g and a 650 kg MTOM was born. Will this become a valid initial military trainer? Franco places great emphasis on robustness and on possible close similarity to the original. “Not only the appearance of the aircraft, but also the methods of construction and the material mix are as original as possible. The “feel” is important to us, not the performance” he says. Under these circumstances, one cannot expect from an aircraft weighing empty 380 kg extreme speed capabilities. The airframes of this replicas are close to the original but engines couldn’t (till now) follow this path. Flying Legend started production using the Rotax 912 ULS engine, the Rotax 914 Turbo was soon implemented and Franco’s own-turbo version of the 912 with some 130HP was introduced. Currently, two first Replicas in Sicilly are Rotax 915iS powered – a logical engine implementation. In this days Franco’s dream powerplant is being installed in the sturdier Tucano Replica airframe, the PBS 240HP turboprop with the 4-bladed DUC prop.

In 2014 the 25-year-old Bruce Ryan Young spent 55 flight hours covering 5700 nm from Brazil to EAA AirVenture Oshkosh. He started in Brazil on July 10 with the Rotax 912ULS powered, amateur-built, Flying Legend and arrived after several stops in the U.S. On July 27. This flight was a huge success and led Franco to open a US subsidiary in Texas where the Italian manufactured parts are assembled and where the turbine version is now being built. Over 60 Tucano Replicas were already sold as kits and RTF aircraft (14 units sold in 2021) in Europe, South Africa, Taiwan, Australia, Brazil, Chile, US and Canada.

Aircraft production

The new Flying Legend plant is just 200 m away from the original production site but it is a completely different world – better to say a different planet. The new big, roomy & clean plant has lots of space for dedicated stations for each aircraft sections – sturdy, heavy jigs. On those jigs all pre-fabricated parts are riveted together. Each worker is in charge for building the part but there is no time pressure. The part should be finished in certain (up-front specified) period of time but each worker can himself decide the tempo of the work. That means the part can be built for example in two or up to four or five days.

I was impressed by the method used for building the single sections. Specially for the wings and control surfaces Flying Legend uses one not common system: the wings are built on heavy steel jigs fixing the parts together with limited number of thin rivets that are smaller than those in finished product (my guess is one instead of 5 to 10 later used in finished part) to assure the final form of the wing. After parts are provisionally fixed together the workers drill all holes needed for final riveting assuring the highest possible parts match. Than the “temporary” rivets are being drilled-out and the wing is dissembled and sent to the customer. Franco want in this way to be sure that the final amateur builder can’t make any mistakes building the aircraft and additionally the builder don’t need any jigs for a perfect shape. For safety reasons the main wing spar is only factory built.

Corrosion protection is another important step. All parts after being cut to shape are then epoxy painted for corrosion protection.

Lot of manufactured parts appear to me to be over-sized in material thickness compared to other similar aircraft. Franco says that his aircraft should last almost forever – somehow I can subscribe that. This is not a common attitude nowadays

Two different Versions

Basically there exist today two versions: one with 600 kg MTOM and + 4.4 / -2.2g load factor and the 650kg MTOM with +6, – 3g. The first is the U.S. LSA born version with fixed gear and qualifies for the Italian/European 600kg UL certification (coming soon) and the other is the experimental/amateur built version with the retractable gear.

The original Tucano was built in the eighties and it was a “chunk of an airplane”. When standing today next to the Tucano Replica, I have the feeling of standing in front of a “real” aircraft – large and heavy, not a toy.

Tucano replica – retractable gear.

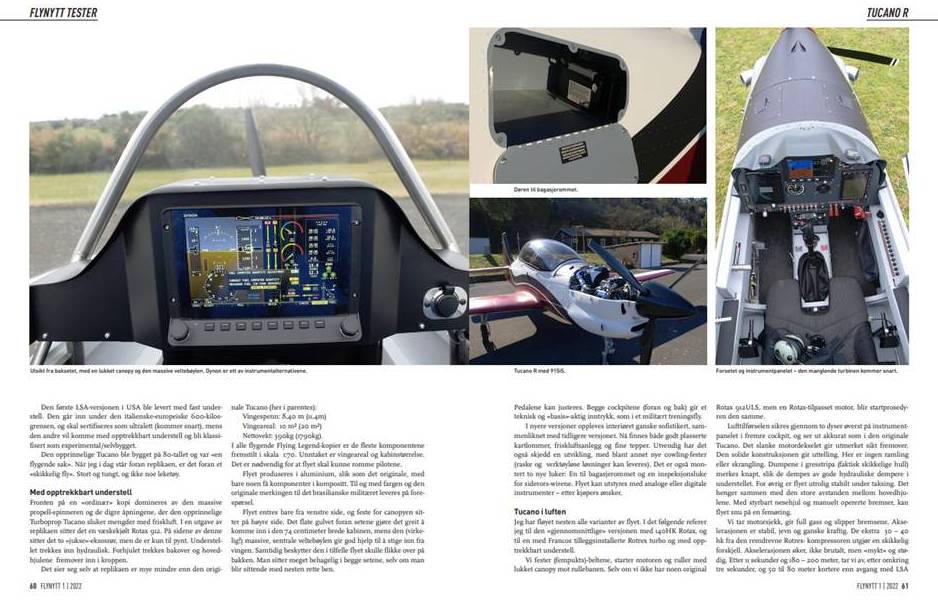

The front of the “normal” replica is dominated by the massive propeller spinner and the huge front opening where the turbine in original Turboprop Tucano sucks fresh air. In a replica a liquid cooler of the Rotax 912 is sitting behind. At the cowling sides two turboprop “fake” exhaust pipes are attached, but do not have any function. The gear legs of the Tucano are hydraulically retractable, the front wheel folds backwards while the main gear legs folds toward the fuselage. The Tucano Replica is of course compared to the original (in parentheses) much smaller: Wingspan 8,40m (11,4m) Wing Area 10 m² (20 m²), net weight 390kg (1790kg). In all Flying Legend Replicas most parts are replicated in a scale 1:70; the wing and the passenger compartment are bigger otherwise the space for the occupants will be too limited. The entire aircraft is metal (aluminum) made, the same as the original. Even the livery and the original labeling of the Brazilian military is being reproduced on demand. Boarding is possible only from the left side because the canopy hinges are on the right cabin sidewall. The flat floor surface -just in front of the seats- additionally eases the entry into the 74cm wide cabin while the massive central roll-bar helps a lot to find a stable stand on the wing and boarding the aircraft. The sitting position is very comfortable on both seats, although the legs are almost horizontal. The rudder pedals are on ground adjustable. Both cockpits (front and rear) look very technical and “basic” – military trainer style.

Today the Tucano interior –compared to the first version – look almost sophisticated, much better refined with map pockets, fresh air vents, and is nicely carpeted. Even externally the aircraft has been improved and has received better engine cowling fasteners (fast & tool-less style available) and two access doors have been installed – one for the baggage compartment access and the second for the empenage controls inspection. The panels can be analog or digital – on customers request.

Tucano’s in flight

I have flown almost all versions of this replica so the below flight data refer to the “medium” available engine – the 140HP Rotax with the Franco’s Rotrex aftermarket turbo installation and with the retractable gear. We fasten the five-point safety belts, start the engine and roll with the closed canopy to the runway. Even having under the cowling not the original Rotax 912ULS engine but a Flygas tuned one the starting procedure is the same. The ventilation is ensured by two air outlet openings at the top of the instrument panel in the front cockpit that look same as in the original Tucano. The slim engine cowling assures excellent forward visibility.

The unevenness of the grass airstrip doesn’t bother the airplane as the hydraulic shocks filter the asperities very well. Thanks to the steered front wheel and manually operated brakes the aircraft can be turned around one wheel. The sturdy aircraft construction pays-off; nothing rattles or creaks. We check the engine, apply full throttle and release the brakes. The acceleration of the aircraft is uniform, steady and pretty powerful. The additional 30-40 HP on board, provided by the Rotrex belt driven supercharger really make the difference. The power increase is not brutal but “soft” and steady. We lift off after 11 seconds and 180-200 meter run, some 3 seconds and 50 to 80 meter earlier as we take-off with the Rotax 912ULS/100HP – Flying the LSA Tucano an hour later with “only” 100 HP under the cowl. We are in the air, the initial rate of climb has risen from 500 to 650 ft/min, we retract the gear and flaps at a speed of 120 kilometers per hour, climbing at a rate of 1000 to 1100 ft/sec. Even in initial climb there is a 200-300 fpm “bonus” coming from the Flygas blower. Although the air is quite turbulent because of fast growing CB-s, the Tucano is very stable – another advantage of the relatively high weight. In level flight, I’m trying to determine the maximum speed. According to my observations, it is 240 km/h compared with 225 kilometers per hour in the LSA version.

The difference of speed between the 140HP, retractable gear, variable pitch prop and the LSA version with non-retractable gear, fix prop and 30HP less is not really excessive and I must admit that I was surprised how well the 100HP version flies. Tucano’s are just replicas which don’t live of extreme speed.

If you need more speed and better climb or better overall performance the newest engine addition, the Rotax 915iS and a 4-blade prop would be probably a worthy investment. With it the Tucano Replica -according Franco – delivers in an experimental RTF version almost 290 km/h TAS top speed (155kts) at 5000ft altitude – but costs you with Dynon glass cockpit 180.000€.

All maneuvers are readily followed by booth Tucano’s versions and I have to say that they are dynamically extraordinary stable – among the best in this category. Even being a scale reproduction of a “nervous” trainer airplane Tucanos are well-behaving aircraft that will not overwhelm even pilots with modest flying experience. Since the aircraft are very stable in the air, you have to “work” with determination on the controls, if you want to have rapid change from one steep turn to the other. Even power on or off stall is nothing out of normal. Usually the nose drops and that’s all.

The view from the seats is like in many tandem aircraft, excellent in all directions except on the back seat, where the head of the front occupant restricts the visibility. With 20 degrees of flaps and 120 kilometers per hour at 800 feet per minute sink-rate we approach the runway; the landing point is not visible even in a base leg so you only can imagine it between the hills. I cut the power and with engine on idle the aircraft gently touch the runway after bleeding a speed. The brakes are sufficiently effective and easy to use even on wet grass.

UL/LSA Tucano Replica

This airplane was the real surprise for me. I was not aware of its existence as it was not shown in public before my flight. I was probably the first journalist that has flown it in 2015. The aircraft, even sharing all firewall-back components with the other Tucano Replica-s, looks radically different. The main difference is its stock Rotax 912 ULS engine, the fixed gear and a fixed pitch propeller. All this makes it eligible for the U.S. LSA category. This move was almost a logical one because the Tucano that went in flight from Brazil was shown to the American public during the AirVenture 2014 in Oshkosh and Franco was able to collect the market feedback. Even this LSA called version is a kind of a prototype because the most visible difference –the engine cowling- will not be stock on the LSA model. The unusual cowling –purchased in the U.S.- was installed to test the possibility to install even biger Lycoming or Continental flat-four engines. This is anyway going to belong to the +6, -4g version. Stock E-LSA kit will be delivered with the Rotax 912ULS “slim” cowling; the new “big” cowling will be an option.

I have flown the LSA called model just after the “normal” Tucano Replica and I must say I was pretty surprised. Why? Because I expected that it will be much slower than the 140HP tuned version with which it shares the whole airframe but it is powered by a stock 100HP engine. Well, there is more drag created by the fixed tricycle gear, the fixed pitch prop and the huge (Lycoming) cowling were adding aerodynamic resistance. Despite all this, the flown version need (see above) just slightly more runway and the overall performance is just approx. 5% lower than the non LSA Tucano. I must admit it flies fine; it is reasonably fast, docile and predictable not feeling under-powered or too heavy. I’m not disappointed with the UL or the “LSA” performance – Franco thought I will be- because the 130HP version is just slightly faster and I have possibly expected more. Interesting, the LSA version uses exactly the same wing as the normal Tucano so the conversion from the fixed-gear to retractable gear is possible. It will require some work but it is doable. In any way the fixed gear UL/ LSA version will be cheaper to build and to operate. The wider cowling (is used) is even in flight slightly limiting the forward view. The interiors on this LSA (prototype) are now much simpler. They are really Spartan but this somehow goes well along the spirit of the airplane.

Prices

So just to recap what was already said in the article. The Flying Legend is offering the Tucano Replica (depending of the version and engine) as a kit, factory assisted building of the kit and as the RTF – Ready-to-Fly variant. For the current pricing please consult the manufacturer and/or his website. Each aircraft can be ordered with fixed and retractable gear (as the base aircraft structure is roughly the same) and in three different kit-production stages. Each kit consists of several sub-kits which can be separately ordered.

The Tucano Replica “Base” kit is 37.000 €, LSA 35.000 €; the kit “Avanzato” – “Advanced” contains pre-assembled parts (fuselage, wings and tail at 49%) and is 49.000€, LSA 42.000€. The third stage is a new option called “Quick build kit Replica” and is basically a total assembled airframe less engine and instruments, priced 65.000€, RTF, the ready-to-fly version starts with

Tucano Replica UL, analog instruments, Rotax 912ULS, 130.000€, Rotax 914 +10.000€, 140HP Rotrex tuned 912 with 130-140HP 130.000€ and the Rotax 915iS version goes for 180.000€

Conclusion

Many manufacturers are today – in the pandemic times- going through hard times and their production rates are sinking toward zero with the consequence of lay-off of the workforce. Franco has sold 14 aircraft in 2021 and the first unit in 2022. In the same moment Flying Legend is expanding and acquiring new – mainly very distant- markets. Not common thing nowadays. The imminent presentation of the PBS 240HP turboprop version in the USA -the “crown” of Flying Legend – is promising even more. This will probably give to Flying Legend a strong sale boost as almost nobody has such a wide power plant portfolio. As I was told there are several other leads even in the (military) trainer market that are promising much higher numbers in close future. Over the years the Tucano’s were improved in tons of details and is today an extraordinary honest, sturdy and sincere aircraft in which you can feel as a military pilot for a day or for the rest of your life. All this combined with the excellent craftsmanship assures an long lasting and stable investment.

The owners of Flying Legend are open to special requests and any aircraft builder will find there competent help. Franco Rumolino knows that he is in a niche of the niche in this market and because of that he can’t afford to delude his customers. The aircraft parts are well built and Franco tends rather to over-build the aircraft adding weight than to save weight, material and save some money.

http://www.flyinglegendusa.com